Our first look will be based on a PURE DEFINITION OF INNOVATION: a patent created by FreeForm founder and CEO Bryan Wilks, in collaboration with Sean Kelly, inventor and design engineer.

THE PROBLEM: While doing business with a furnace packaging company, Bryan and Sean both discovered something seriously wrong: an inefficient design. All homes need the basic necessity of warmth and a furnace packaging company is one of the steps on the long path of fulfilling that need. In Bryan and Sean’s case, the customer was shipping furnaces originating in the U.S. to locations all over the country, Canada, and Mexico. At the time, the packaging was made of corrugated materials and foam, which meant a lot of labor was required to package the parts on the assembly line. With high labor rates in the U.S., more labor meant more money, and each dollar spent in turn meant more time per furnace.

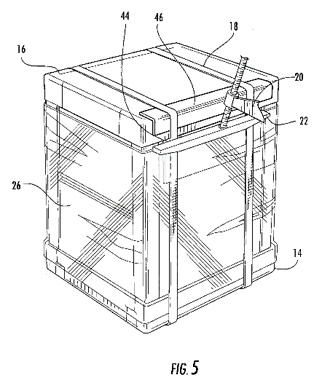

THE SOLUTION: Bryan and Sean both looked at the inefficiency and decided there must be a better way to package. Sean went out and benchmarked the competition—scouring various Home Depot and Lowe’s stores and scoping out the various packaging methods done by alternate companies. What he found was that everyone was essentially doing it the same way—using similar corrugated packaging designs that all served the same inefficiencies and same high costs of production. What did this mean? An opportunity. Their thought process was that this problem presented an opportunity to be first with something “completely new, completely different,” said Sean. Bryan and Sean immediately got the ball rolling. At the drawing board, they came up with various ideas, using differing materials and estimating time and production costs for each. The trick was logistics. They had to handle equipment that was very specific to the furnace industry, keeping in mind the tactics the customer already used, such as spade lifting and conveyer line packaging. Bryan and Sean combined corrugated material with clear film, eliminating the burdensome plastic box of the past, and incorporating tracking, which enabled operators to handle the furnace the same way they did before. Nobody had ever developed a clear pack that could be handled by the methods already used in the industry and that’s exactly what they did. “It would change the way [packaging] worked, and the way we think,” said Sean.

Innovation at its finest. With this brand new idea, furnaces were able to be handled the same way, preserving the millions already invested in forklifts and conveyer belts. All the while, this reduced labor in the packaging process and increased profit without requiring a massive investment in logistics and handling. The new packaging could be applied by machine instead of by hand, saving both money and time while being more consistent. Better yet, through the newly designed clear pack, accidental damage to the product in the shipping process could be identified early by the distributor, enabling time and money to be saved on returns, if need be, and ensuring customer satisfaction tenfold. In fact, a CEO of a major appliance manufacturer stated, “This design allows us to see damage before it leaves our production facilities and reduces, if not eliminates, product claims. It’s a big deal.”

The new idea was laced with benefits for the entire process and would save thousands of dollars in both labor and time. One idea: fostered not only by smart minds with creativity, but by idea engineers. That’s exactly what FreeForm consists of: idea engineers with determination to push ingenuity to the next level and build the visions of tomorrow.

While in study at Harvard, I myself see the roots in innovation everywhere around me. In my Mechanical Engineering class, ideas are put to the test from a practical standpoint, being physically crafted and designed. In lectures and studies, professors speak of the new tomorrow—of where society will be and where we will be, and how we will contribute to the revolution of the future. Many students have the mind to create a plethora of ideas that can define the essence of tomorrow, yet these ideas are left on a limited drawing board, only to be forgotten. At FreeForm, I see the company from both an inside and outside perspective and what I see is a living, thriving drawing board. With marketing, every idea is valuable, but it must be put to use and put to the test. FreeForm allows an idea to live, breathe, and grow in an environment that will ultimately provide benefits to the holder, and turn into the next groundbreaking innovation.

Most marketing companies are stuck on the ideas of yesterday. We at FreeForm focus on the ideas of tomorrow—to revolutionize today and go head-to-head with innovation at its finest. Our approach: design thinking. Think. Feel. Do. Through desirability, feasibility, and viability, we redesign the idea of innovation and, through it, rediscover the world through a new lens.